Modular SIL 3 Wireless Foot Pedal Solution

Lazer Safe’s new wireless foot pedal solution is a modular technology, allowing press brake manufacturers to seamlessly integrate SIL 3 wireless functionality.

Lazer Safe’s new wireless foot pedal solution is a modular technology, allowing press brake manufacturers to seamlessly integrate SIL 3 wireless functionality.

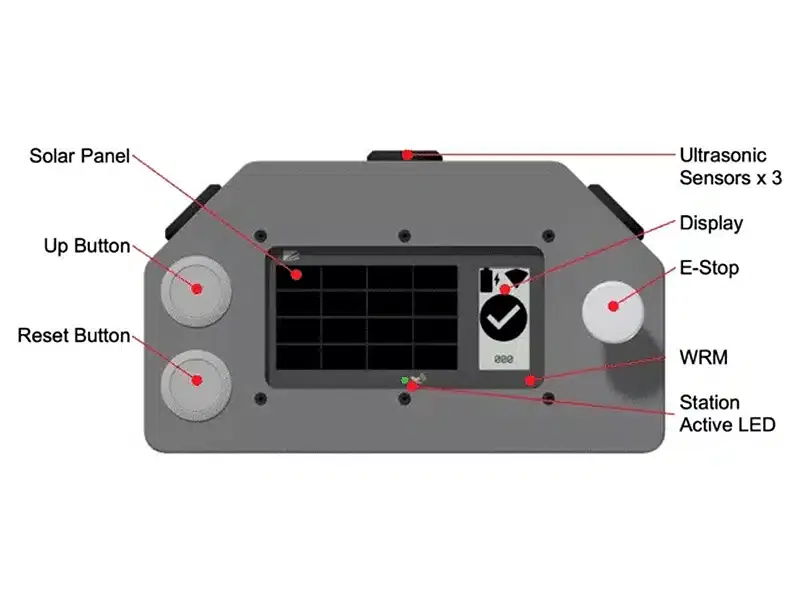

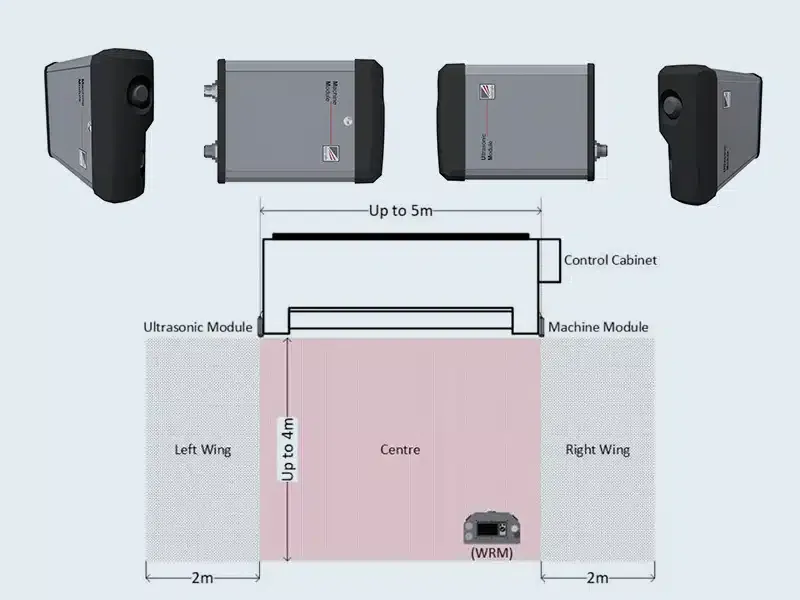

Our wireless foot pedal solution is now available as an optional feature for press brake manufacturers utilizing the PCSS-A1 or PCSS-A2 platform. This solution makes it effortless to incorporate wireless functionality into your machines by integrating the wireless module into your existing foot pedal or by designing a new pedal from scratch. The wireless system employs a secure, dual-channel SIL 3 communication method that enables two-way communication between the press brake and the foot pedal. Additionally, the system employs ultrasonic sensors to provide dynamic range and position monitoring. Please note that the image shown is an example of an OEM foot pedal layout.

Introducing the newest version of our WEIYA foot controls, tailored for customers seeking a clutter-free workspace around their machine. Our wireless pedal system comprises three key hardware components:

Our wireless pedal system consists of a Wireless Remote Module (WRM), which is integrated inside the foot pedal. Additionally, the foot pedal contains a set of three ultrasonic sensors.

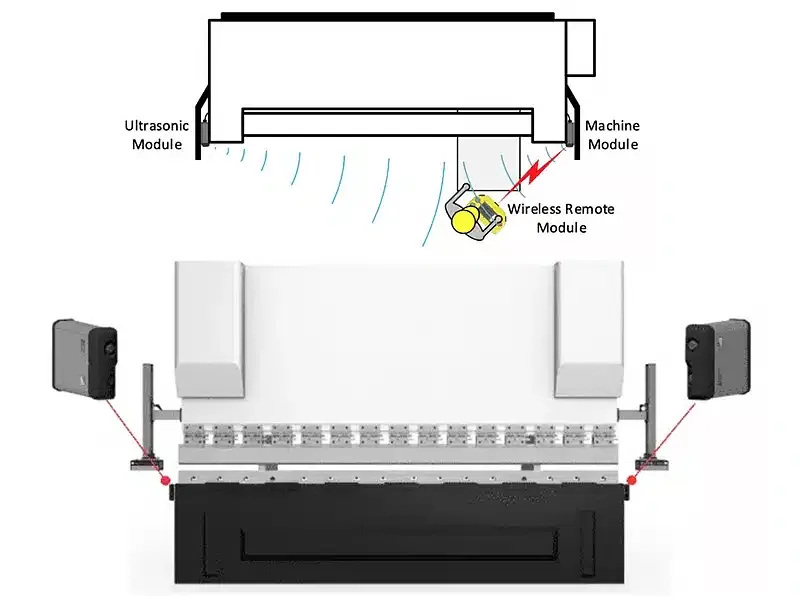

The Machine Module (MM) is installed on the press brake and serves as the wireless link between the WRM and PCSS-A.

The Ultrasonic Module (UM) is mounted on the press brake, and in conjunction with ultrasonic sensors in the MM, it monitors the position of the foot pedal.

The wireless remote module is a self-contained unit that includes:

12 pulsed safety inputs (6 dedicated and 6 spare).

Dual integrated antennas

E-paper display

Indoor solar charging cell

Rechargeable lithium ion battery

Connections for external USB charging port and wireless pairing button

Pedal active status LED

An illuminated (red LED) emergency stop button

A set of three ultrasonic sensors of the 12 inputs on the WRM, 6 inputs are preconfigured for the following functions;

Down pedal x2 (NO and NC contacts)

Emergency stop button x2 (NC contacts)

Reset button x2 (NO and NC contacts)

Of the remaining 6 spare inputs, these can be custom configured for any auxiliary button functions such as the up pedal, upper and lower tool clamping, etc.

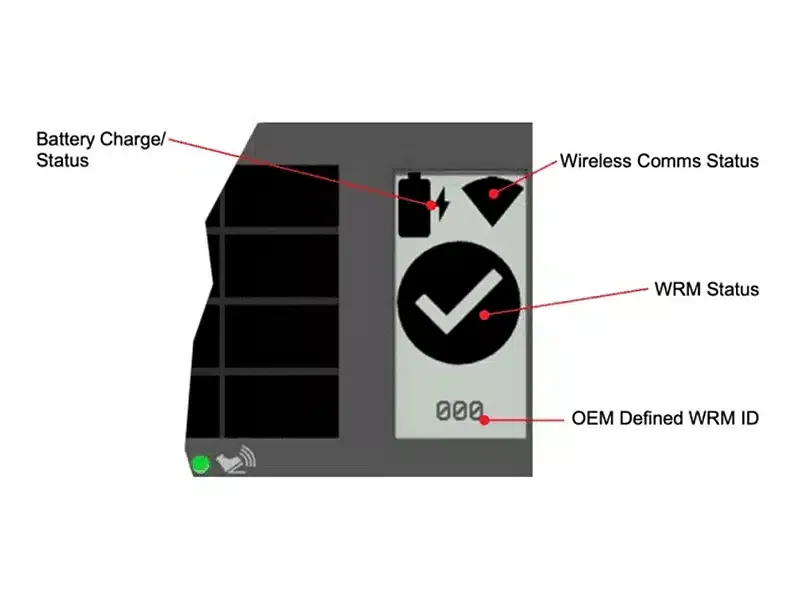

The low-power display shows information to the machine operator such as battery level, wireless signal strength and in-range status. The foot pedal identification number can be defined by the press brake manufacturer and also displayed on the CNC to show the operator which foot pedal is paired with the machine.

The Machine Module (MM) and Ultrasonic Module (UM) are fitted to the lower front left and right ends of the press brake. The MM is mounted on the press brake and interfaces between the PCSS-A and the Wireless Remote Module (WRM). The MM communicates wirelessly with the WRM, and also contains a set of two ultrasonic sensors. The UM contains an additional two ultrasonic sensors. The total combination of seven ultrasonic sensors located in the WRM, MM and UM are used to triangulate the position of the foot pedal in relation to the front of the press brake.

The Machine Module (MM) and Ultrasonic Module (UM) are fitted to the lower front left and right ends of the press brake. The MM is mounted on the press brake and interfaces between the PCSS-A and the Wireless Remote Module (WRM). The MM communicates wirelessly with the WRM, and also contains a set of two ultrasonic sensors. The UM contains an additional two ultrasonic sensors. The total combination of seven ultrasonic sensors located in the WRM, MM and UM are used to triangulate the position of the foot pedal in relation to the front of the press brake.