Have you ever wondered how a flat sheet of metal transforms into the curved edges of a car door, the sharp angles of a kitchen cabinet, or the precise brackets holding your smartphone? Chances are, a press brake made it happen. This powerful machine is the unsung hero of metal fabrication, shaping the world around us with remarkable precision. But what exactly is a press brake, how does it work, and why do manufacturers rely on it so heavily? Let’s explore the most searched questions about this essential tool.

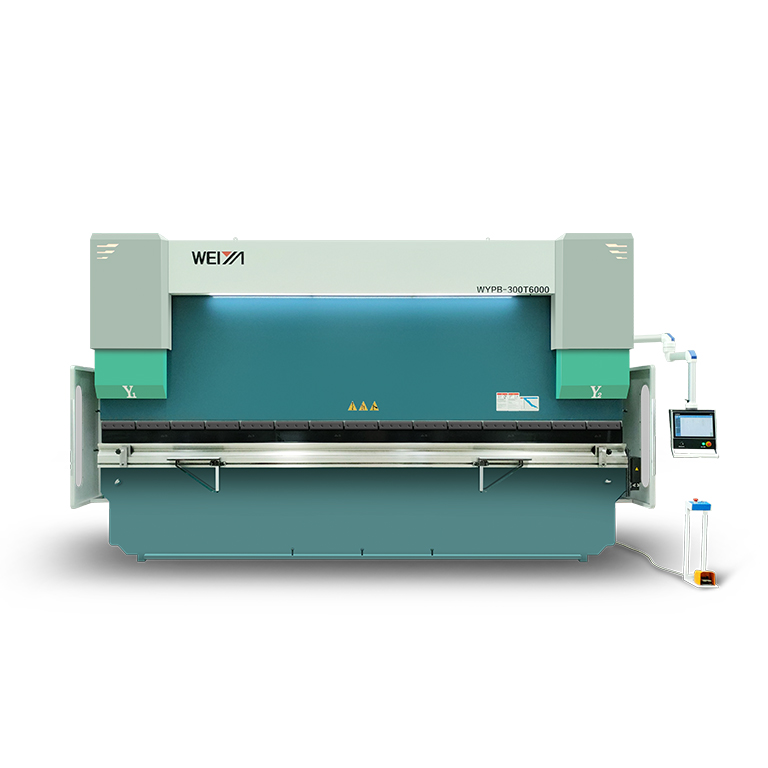

At its core, a press brake is a machine designed to bend metal sheets into specific shapes using force and specialized tools. Think of it as a giant, super-strong "metal folder" – but instead of paper, it handles steel, aluminum, and other tough materials. Unlike roll-forming machines that create continuous bends (like pipes), press brakes excel at making precise, sharp angles or custom curves in individual workpieces, from small brackets to large structural panels.

The magic lies in its ability to control two key factors: force (how hard it presses) and precision (exactly where and how the bend happens). This makes press brakes indispensable in industries ranging from automotive manufacturing to aerospace, construction, and even consumer electronics.

You don’t need an engineering degree to understand the press brake’s core function. Here's a step-by-step breakdown of its operation:

1. Setup: A metal sheet is placed on a flat lower table, aligned using guides called "backgauges" (think of them as rulers for metal). These backgauges ensure the sheet is positioned perfectly for the desired bend.

2. Die Selection: A V-shaped or custom die is attached to the lower table. The size of the die's V-opening depends on the metal's thickness – for example, thin aluminum uses a smaller V than thick steel to avoid cracking.

3. Bending Action: The machine's upper beam (called a "slider") descends, pressing the metal into the die with immense force. This force bends the metal beyond its elastic limit, making the shape permanent.

4. Springback Compensation: Metals naturally "spring back" slightly after bending. Modern press brakes use smart technology to over-bend slightly (e.g., bending to 88° for a 90° final angle) to counteract this effect.

It's like folding a piece of cardboard, but with mathematical precision and tons of force – literally! A typical press brake can exert anywhere from 50 to 2,000 tons of pressure, enough to bend steel plates several inches thick.

Not all press brakes are created equal. The three main types, often searched by manufacturers, cater to different needs:

These are the "workhorses" of high-volume production. Powered by a flywheel and crankshaft, they offer fast, consistent bending for simple, repetitive tasks like making identical brackets.

•Best for: Thin to medium metal sheets (up to 6mm steel) and high-volume jobs.

•Pros: Fast cycling speed and lower upfront cost.

•Cons: Less flexibility for complex bends or thick materials.

Using hydraulic cylinders to generate force, these machines are the most versatile. They adjust easily to different metal thicknesses and bend angles, making them a shop favorite.

•Best for: Custom jobs, thick metals (up to 50mm+), and small-batch production.

•Pros: Precise force control and ability to handle diverse materials.

•Cons: Slower than mechanical models and require regular hydraulic fluid checks.

The "smart" option, combining hydraulic power with computer control. CNC (Computer Numerical Control) systems store bend programs, ensuring perfect repeats for complex parts like aerospace components.

•Best for: High-precision work (tolerances as tight as ±0.1°) and complex multi-bend parts.

•Pros: Automation reduces errors; energy-efficient servo motors cut electricity use by 40-60%.

•Cons: Higher initial cost, but saves money long-term on labor and waste.

Pro Tip: New hybrid models now blend hydraulic power with electric efficiency, ideal for shops wanting both precision and eco-friendliness.

Even the best machines hit snags. Here are the most searched troubleshooting issues:

If your 90° bends are coming out at 88° or 92°, check:

•Material Thickness: Use a micrometer to confirm the sheet matches your settings – a 2.2mm sheet needs a different die than a 2mm one.

•Worn Dies: Chipped or dull dies (the bending tools) cause uneven pressure. Replace or sharpen them.

This happens when force is too high or dies are mismatched:

•Reduce Tonnage: Too much pressure can split thick steel or brittle aluminum.

•Choose the Right Die: Use a larger V-opening for thick materials (e.g., 10×t for high-strength steel) to distribute force evenly.

Strange sounds or heat mean trouble:

•Lubricate Moving Parts: Grease bearings and gears to quiet noise and reduce friction.

•Check Hydraulics: Low oil levels or leaks cause overheating – top up fluid and fix leaks promptly.

Press brakes are powerful, so safety is critical. Here's what users search for most:

•Eye Protection: Safety glasses shield from flying metal debris.

•Hearing Protection: Loud machines (up to 85dB) require earplugs.

•Guards and Light Curtains: These electronic barriers stop the machine if hands enter the bending area – never bypass them!

•Never reach into the bending area while the machine is running.

•Use two-hand controls (both hands on separate buttons) to prevent accidental activation.

•Keep the workspace clean – clutter causes trips and mistakes.

Searching for "how to pick a press brake"? Start with these questions:

•Thin aluminum or stainless steel? A 100-ton CNC model works.

•Thick high-strength steel (10mm+)? Opt for a hydraulic press brake with 200+ tons of force.

•High-volume, simple bends? Mechanical press brakes save time.

•Custom, low-volume parts? CNC models reduce setup time between jobs.

Use this simple formula for carbon steel:

Tonnage = Length (m) × Thickness (mm) × 8

For stainless steel, multiply the result by 2 (it's stronger!). Example: Bending a 3m long, 3mm carbon steel sheet needs 72 tons.

Press brakes shape more than just metal – they enable innovation:

•Automotive: Car manufacturers use automated press brakes to bend door panels with 80% faster cycle times than manual methods.

•Aerospace: Titanium aircraft parts require CNC precision to meet micron-level tolerances for safety.

•Architecture: Skyscrapers like Dubai's geometric facades rely on custom-bent metal panels shaped by large hydraulic press brakes.

•Electronics: Your laptop's slim aluminum casing? Bent to perfection with a low-tonnage CNC press brake.

As technology advances, press brakes are getting smarter:

•AI Springback Compensation: Cameras and algorithms adjust bends in real-time to eliminate errors.

•Eco-Friendly Hybrids: Servo motors cut energy use by half compared to older hydraulic models.

•3D Integration: Designers can now send 3D models directly to CNC press brakes for instant production.

From your morning coffee machine to the bridge you drive over, press brakes shape the modern world. They blend raw power with delicate precision, making them irreplaceable in manufacturing. Whether you're a hobbyist curious about metalworking or a professional shopping for a machine, understanding the basics of press brakes helps you appreciate the craftsmanship behind everyday objects.

Next time you see a bent metal part, you’ll know – a press brake made it possible!