Metal fabricators today face growing demands for precision, speed and versatility in sheet metal processing. WEIYA's advanced fiber laser cutting technology delivers all three while maintaining cost-efficiency - a combination that's reshaping industry standards globally.

WEIYA Laser Cutting Machines combine high-power fiber laser sources with precision motion systems to achieve cutting speeds up to 120m/min and positioning accuracy of ±0.03mm, making them ideal for both high-volume production and intricate prototype work. Our 20+ years of OEM experience ensure these performance benchmarks translate reliably to your workshop floor.

Modern fabrication requires machines that outperform traditional cutting methods in every measurable category - speed, precision, material efficiency and operational costs.

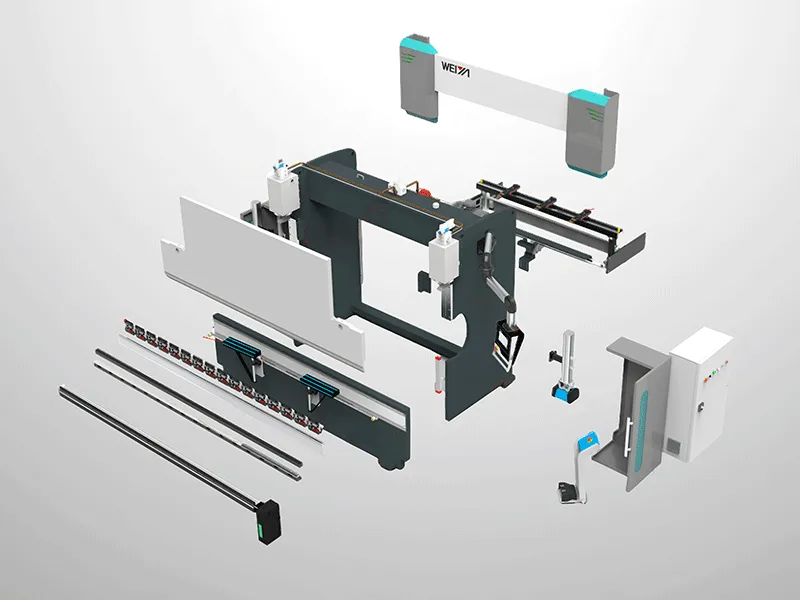

WEIYA Laser Cutting Machines feature IPG or Raycus fiber laser sources ranging from 500W to 12,000W, paired with high-rigidity gantry systems and linear guides that maintain micron-level accuracy even during continuous operation. This German-Chinese component synergy delivers exceptional performance across multiple material types:

| Material | Thickness Range | Cutting Speed* |

| Mild Steel | 0.5-25mm | Up to 25m/min |

| Stainless Steel | 0.5-20mm | Up to 15m/min |

| Aluminum | 0.5-16mm | Up to 10m/min |

| Copper | 0.5-8mm | Up to 8m/min |

*Speeds vary based on laser power and material thickness

German-brand fiber laser sources

Precision linear guideways

High-torque servo motors

Automatic nozzle changing systems

Integrated cutting head protection

The true value of laser cutting extends far beyond the initial purchase price through multiple operational efficiency channels that positively impact profitability.

By switching to WEIYA Laser Cutting Machines, shops typically achieve 30-50% material savings through optimized nesting software, plus 40% faster processing times compared to mechanical cutting methods. Our machines also reduce secondary operations through superior edge quality.

Reduced Material Waste

Intelligent nesting software maximizes sheet utilization

Narrower kerf widths preserve more material

No tooling changes required between jobs

Labor Efficiency Gains

One operator can manage multiple machines

Minimal setup time between jobs

Automated loading/unloading options available

Energy Efficiency

Fiber lasers consume less power than CO₂ alternatives

Smart power management systems

Lower cooling requirements

From automotive components to architectural metalwork, modern laser technology has revolutionized fabrication possibilities across industries - if you choose the right equipment partner.

WEIYA Laser Cutting Machines excel in both high-mix/low-volume prototyping and high-volume production environments, handling everything from delicate medical components to heavy plates for agricultural machinery. Our global client base demonstrates this versatility:

Automotive parts manufacturing

Electrical enclosures and panels

Kitchen equipment and appliances

Signage and decorative metalwork

Agricultural machinery components

Elevator and escalator parts

Various bed sizes (1500x3000mm to 4000x20000mm)

Exchange tables for continuous operation

Automatic loading/unloading systems

Dust and fume extraction integration

Specialized cutting heads for unique materials

WEIYA Laser Cutting Machines represent the smart convergence of German-Chinese engineering excellence, delivering unmatched precision and productivity gains while reducing operational costs - a formula that benefits both fabricators and equipment distributors globally.