When metal needs to transition from flat to three-dimensional, the bending machine becomes an indispensable shaping tool in metal processing. Whether it's precision edge folding for auto parts production, right-angle forming in electrical cabinet assembly, or arc polishing in medical device manufacturing, this tool controls every bending angle with millimeter-level precision—from subtle 15° bends to 180° closed hems. It effortlessly handles common metal materials such as carbon steel, stainless steel, and aluminum alloy.

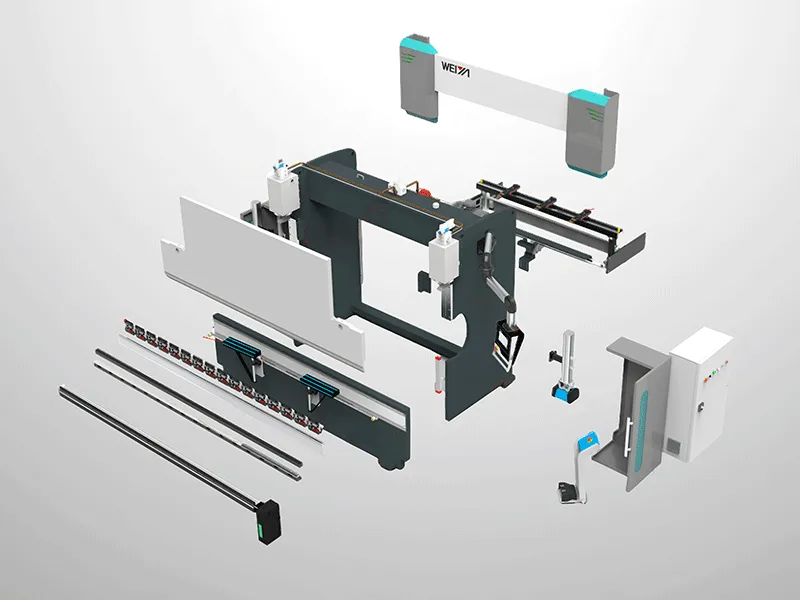

As an upgraded intelligent processing tool, the CNC bending machine breaks the limitations of traditional operations: it can store 100 sets of processing parameters for one-click recall, eliminating repeated debugging. Equipped with a hydraulic drive system combined with servo motors, it increases bending speed by 30% while maintaining strict error control within ±0.1°. Whether for mass production of standard workpieces or custom processing of special-shaped components, every fold becomes a testament to quality, upgrading metal processing from "barely meeting standards" to "precision-controlled excellence."

Faced with coiled steel plates and thick aluminum sheets, the shearing machine serves as the core tool for "primary cutting" in metal processing workflows. Boasting three key advantages—stability, speed, and precision—it acts as the "guardian of the first pass" in transforming metal raw materials into usable components. Whether cutting 1mm-thin metal sheets smoothly or severing 20mm-thick steel plates cleanly, this tool achieves burr-free and deformation-free cutting results through sharp alloy blades and powerful shearing force, significantly reducing subsequent grinding and correction processes to save production time.

As a more efficient cutting solution, the CNC shearing machine further maximizes processing efficiency: it features a touchscreen visual operation interface supporting graphical programming, enabling novice operators to master it quickly. The automatic feeding system combined with precise positioning devices ensures cutting accuracy of ±0.05mm, increasing daily processing capacity by over 50%. From sheet metal preprocessing in large-scale steel structure production to mass cutting of small hardware parts, its reliable "one-cut forming" performance accelerates the transformation of metal raw materials into usable components, reducing production time costs.

When metal processing precision exceeds the limits of physical cutting, the laser cutting machine emerges as an intelligent tool in precision metal processing, acting as an "invisible sharp blade." Leveraging a high-energy-density laser beam, this tool enables ultra-precise cutting on various metal materials such as carbon steel, stainless steel, and brass. Whether engraving complex patterns, drilling micro-holes, or cutting precise special-shaped contours, it achieves smooth cuts and flat edges without the need for secondary processing.

The intelligent laser cutting machine also combines high efficiency and flexibility: adopting fiber laser technology, it cuts 2-3 times faster than traditional cutting tools while consuming less energy, aligning with energy-saving production requirements. It supports instant import of arbitrary graphics for processing, seamlessly switching from single-piece custom production to mass production without complex adjustments. In fields such as precision instrument manufacturing, auto parts production, and advertising sign making, its "zero-error" cutting performance becomes a key tool for enterprises to improve product quality and enhance market competitiveness.