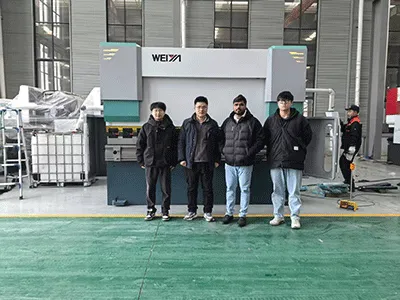

DELEM Tools for Press Brake Productivity

DELEM DA-Offline software boosts press brake efficiency and production output, while Profile-T3D enables offline programming and simulation of the bending process.

DELEM DA-Offline software boosts press brake efficiency and production output, while Profile-T3D enables offline programming and simulation of the bending process.

Full scale offline programming

Graphical product programming and bend sequence generation

Feasibility studies and production preparation

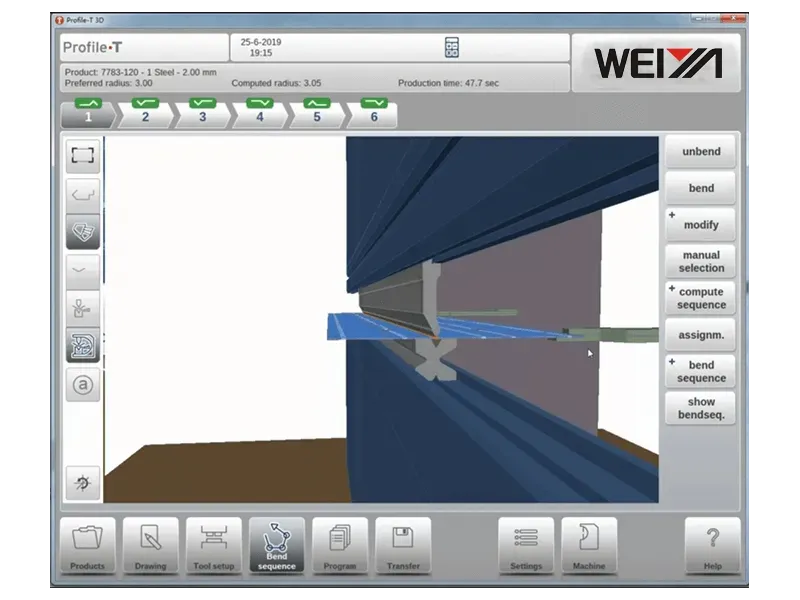

2D/3D automatic bend sequence calculation

Collision detection

Product sharing over Windows networking with press brake CNC

Machine setup preparation including print functionality

Production time calculation

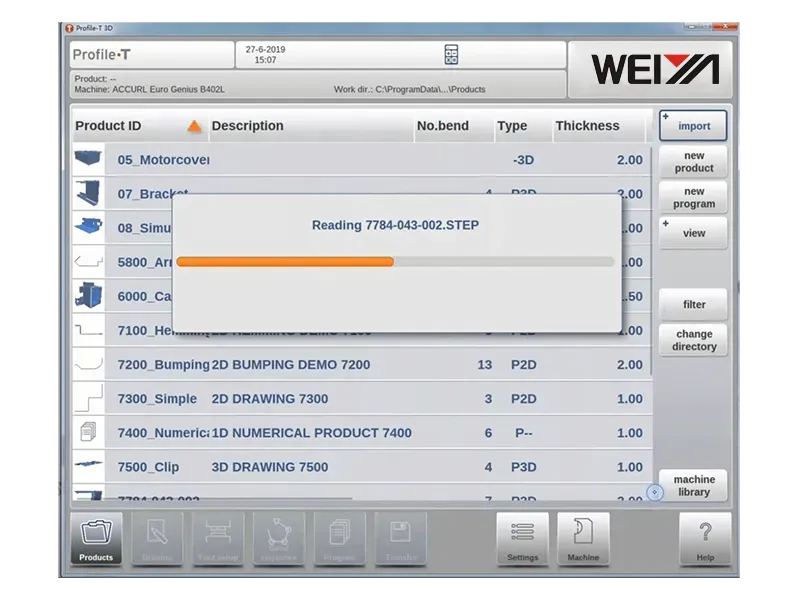

DXF tool and product import

3D CAD product import

The Bending offline software is an essential tool for maximizing the profitability of any CNC press brake machine. With the Profile-T3D offline software, you can import and unfold 3D files quickly, easily, and efficiently, automatically finding solutions for tooling and bend sequences, and dynamically simulating in 3D to check for collisions.

The software allows for a range of production preparation tasks, including makeability and tooling verification, operator training, and adding production notes. Additionally, many other functions can be performed offline to streamline the production process.

The Profile-T3D software provides advanced programming in both 2D and 3D, seamlessly integrating with the DA-Touch controller software. The user interface clearly guides the programming process from start to finish, including transferring the program to the control. Overall, the Profile-T3D software is an invaluable tool for optimizing the production of sheet metal parts on a CNC press brake machine.

The Profile T3D application is designed for programming and simulating Press Brakes machines equipped with CNC technology. Its purpose is to boost productivity, minimize downtime, and reduce material wastage. The software allows users to program products graphically, providing a true-to-scale representation of the intended product. Realistic product visualization is also available, giving feedback on the feasibility of the design and identifying potential collisions, required tools, and tool adapters for production. Additionally, special operations such as hemming bends and bumping are supported graphically, providing a comprehensive preview of the bending process.

The DA-Offline range is an integrated solution that combines offline preparation with press brake operations, resulting in optimal machine efficiency.

By allowing for offline preparations that align with the machine functions, valuable production time can be saved. After all, productivity is the ultimate goal!

Understanding the control is essential for comprehending the offline solution, as it provides a sense of familiarity and comfort that can improve acceptance of the technology.

Ensuring compatibility of functions across versions requires the use of the appropriate software that is compatible with the control system. This is not only logical but also critical for ensuring seamless operation.

Working online, with both the office and the machines, can increase availability and prevent mismatches. By using one source for both the office and the machines, the potential for errors is minimized, resulting in a more streamlined and efficient production process.

| Versions | 2D or 3D programming version |

| Visualisation | 3D machine representation |

| Programming aid | X1-X2 angle programming |

| Finger visualisation | 3D finger view |

| User interface | DA-Touch familiar user interface |

| CAD import | DXF import functionality (Profile-T2D upwards) |

| CAD import DXF import functionality (Profile-T2D upwards) 3D CAD import functionality (ProfileT-3D) |

Importing and unfolding of Solid Works 3D parts in IGES, STEP formats

Full-scale offline programming

Graphical product programming and program generation

Full 3D automatic bend sequence calculation

Automatic calculation of the back gauges backing

Product sharing over Windows networking with press brake

3D simulation of the bending process with collision detection

Automatic and manual fingerstop positioning with graphic control of all axes.