Laser Safety System: Workplace Safety Enhancement

The laser safety protection system adopts efficient laser detection tech to effectively prevent operators from touching the machine’s moving parts and enhance workplace safety levels.

The laser safety protection system adopts efficient laser detection tech to effectively prevent operators from touching the machine’s moving parts and enhance workplace safety levels.

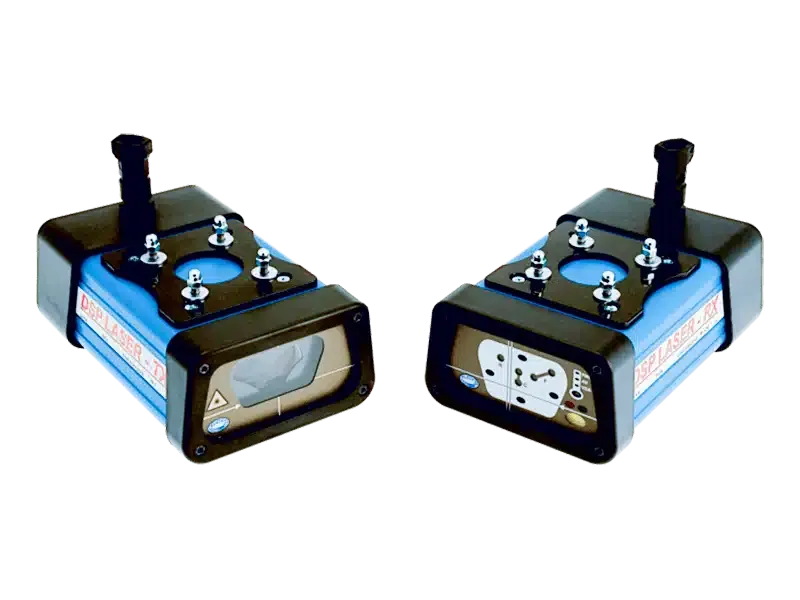

If you prioritize safety, integrating the Italian DSP® laser protection system is crucial. This system features a multi-beam receiver for comprehensive laser protection of the front, middle, and rear areas, achieving safety levels of CAT.4 and SIL3. It has an IP65 enclosure protection rating, a Class 1M laser rating, a response time of only 5 milliseconds, an operating temperature range of 0°C to 50°C, and is installed on the upper crossbeam. The speed change point is 5 mm + stopping distance, with a maximum protection distance of up to 15 meters. Various operating statuses are displayed in real-time via LED indicators.

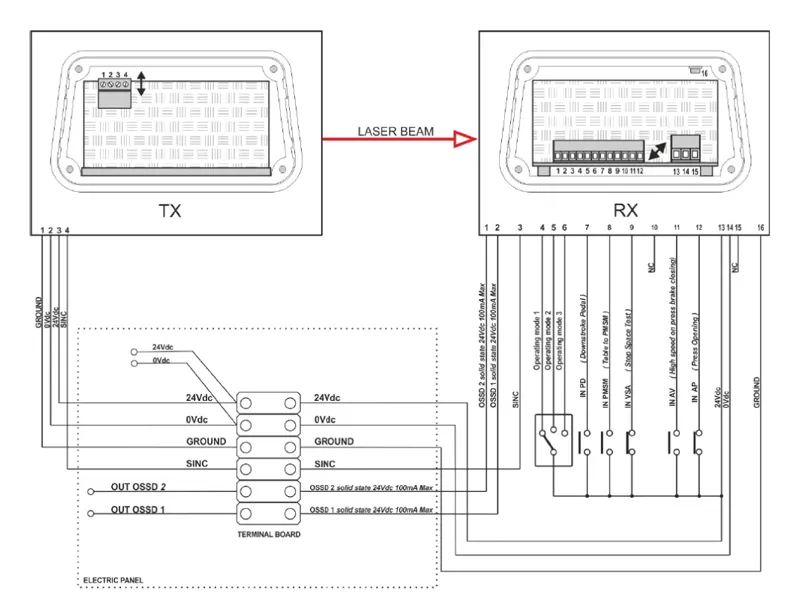

The DSP LASER AP safety device is a visible laser barrier designed to protect press brake operators from being crushed between the upper and lower tools when the press is rapidly closing. It meets the safety standards set forth in EN12622. The device comprises a transmitter (TX) that emits the laser and a receiver (RX) that detects it and processes the received signals using the MCS module. The MCS module can manage a large number of signals and perform various machine functions.

The WEIYA CNC Press Brake incorporates OEM EMBEDDED LAZERSAFE, providing a superior solution for enhancing operator safety and machine productivity. Lazer Safe’s PCSS A Service is designed to work seamlessly with the press brake, and the Lazersafe system is compliant with Category 4 safety requirements and meets the most stringent international safety standards. Additionally, the system includes a CE Certified Category 4 Safety Controller with integrated features.

OPTIONAL:

Lazersafe-PCSS A0 LZS-XL

Lazersafe-PCSS IRIS

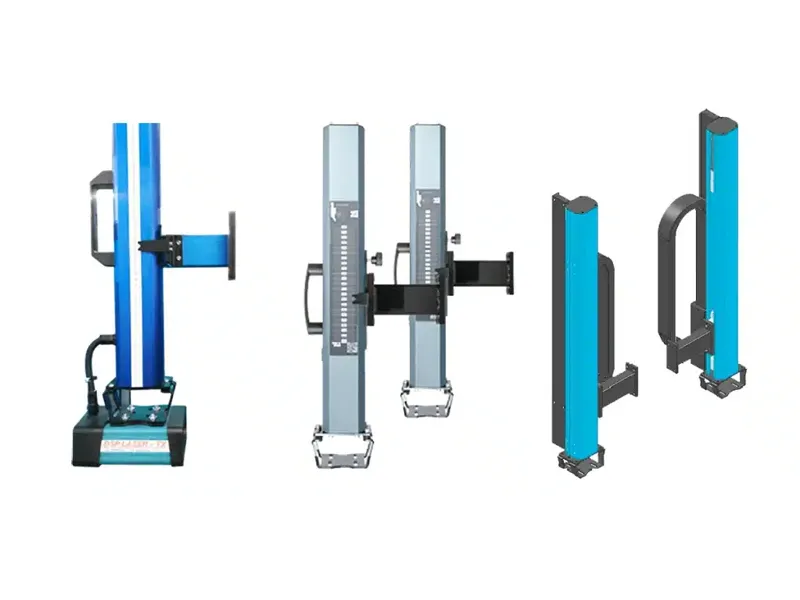

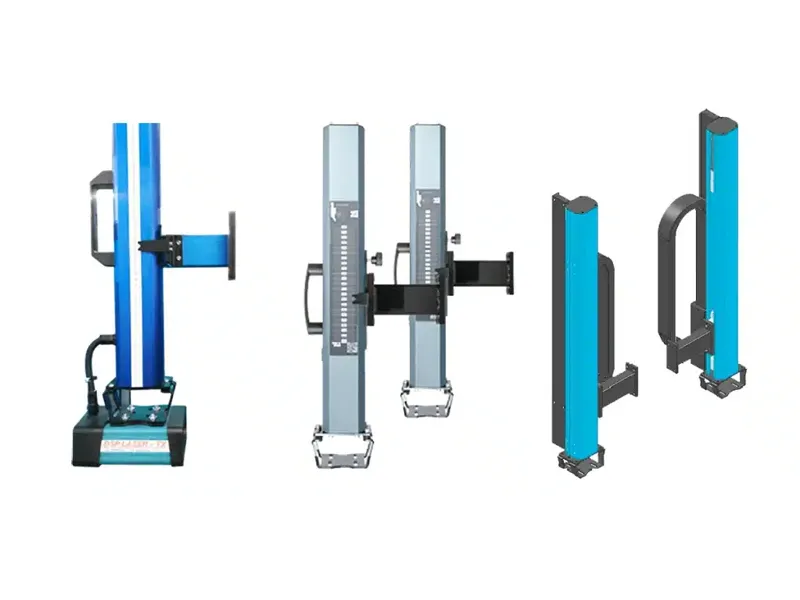

Brackets are mandatory safety devices that enable proper installation of injury-preventing photocells on press brakes. We offer brackets with varying running strokes to meet your specific needs upon request.

Technical Features

Aluminum structure,strong and stability

Easy to install,Multi-directional adjustable

Equipped with scale,Adjust according to the

height of the punch

Practical,fast and competitive price

They can be managed using CNC and Barcode Scanner Reader technology, offering various benefits:

Immediate adjustment

Available in different formats

Great range of displacement

Suitable for any type of machine

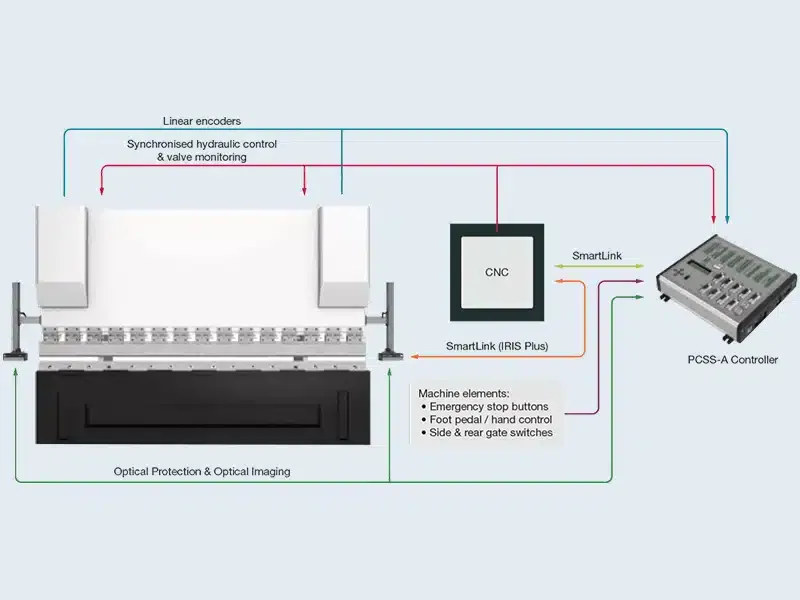

Both the IRIS and IRIS Plus models are combination systems that offer high-performance optical protection during high-speed tool closing. Once the bending process commences, image processing functions take over. These systems capture and process images in real-time and transfer live data to the CNC system via SmartLink. The image processing system is fully integrated within the IRIS and IRIS Plus receivers, eliminating the need for additional hardware or software.

The European press brake standard EN12622 limits bending speed to 10mm/s to ensure a basic level of operator safety by regulating the speed at which material facing towards the operator moves during bending.

However, the machinery directive and EN12622 have provisions for faster bending speeds with wider V dies, as long as certain operations can be adequately monitored. In the CNC system, manufacturers can set faster bend speeds for wider V dies, and the Bend Speed Management process automatically monitors the material’s speed as it moves through its bending arc, facilitating a safe condition for faster bending.

Systems with camera receivers offer automatic tool alignment, eliminating the need for precise manual adjustments. This process can be fully automated in the CNC via SmartLink, which eliminates the need for the operator to press the TOOL ALIGN button.

The OEM Embedded Systems LZS Series and IRIS Series hardware and software are CE Certified and comply with all international press brake safety standards, including EN12622, ANSI B11.3-2012, CSA Z142-10, and NR12.

The PCSS-A is a programmable safety controller that enhances both the performance and safety of press brakes. It provides press brake manufacturers with flexibility and streamlines the design process by integrating all control, safety, and monitoring functions into a single system, eliminating the need for complex integration of third-party components and software. The PCSS-A delivers an optimal balance of functionality and performance with reduced build costs. This provides an efficient and cost-effective platform with fewer components, reduced wiring, a simplified interface, and CE Certified hardware and software to minimize engineering and build time.

| PCSS-A0 | PCSS-A0 PLUS | PCSS-A1 | PCSS-A2 | |

| Technology | ||||

| SmartLink | ||||

| FlexSpeed | ||||

| AutoSense | Plus | Ultimate | Ultimate | Ultimate |

| Specifications | ||||

| Safety inputs | 12 | 12 | 16 | 16 |

| Safety outputs | 4 | 4 | 6 | 6 |

| Standard inputs | 24 | 24 | 28 | 28 |

| Standard outputs | 6 | 6 | 10 | 10 |

| Linear encoder I/O | 1, Y1 or Y2 | 2, both Y1 and Y2 | 2, both Y1 and Y2 | 2, both Y1 and Y2 |

| Minimum encoder resolution | 0.1 micron | 0.1 micron | 0.1 micron | 0.1 micron |

| Speed capacity of the encoder counters | >300mm per second | >300mm per second | >300mm per second | >300mm per second |

| Response time (hardware interrupts) | <1ms | <1ms | <1ms | <1ms |

| SD Card (back-up, data logging and high-speed software transfer) | ||||

| CAN Open | ||||

| Ethernet | ||||

| Ether CAT | OPTIONAL | |||

| Dimensions | 229mm x 189mm x 45mm | 229mm x 189mm x 45mm | 229mm x 189mm x 45mm | 229mm x 189mm x 57mm |

| Expansion Options | ||||

| Tandem Adaptor | ||||

| SmartLink Brackets | – | – | • | • |

| Wireless Foot Pedal | – | – | • | • |

| Optics Compatibility | ||||

| LZS-1 | • | • | • | • |

| LZS-2 | • | • | • | • |

| LZS-XL | – | – | • | • |

| IRIS / IRIS Plus | – | – | • | • |

| Third party light curtain support | • | • | • | • |

| Dual guarding support | • | • | • | • |

| LZS-1 | LZS-2 | LZS-XL | IRIS | IRIS PLUS | |

| Optical protection functions | • | • | • | • | • |

| Optical imaging functions | – | – | – | • | • |

| Laser transmitter | CLASS 1 | CLASS 1 | CLASS 1 | CLASS 1 | CLASS 1 |

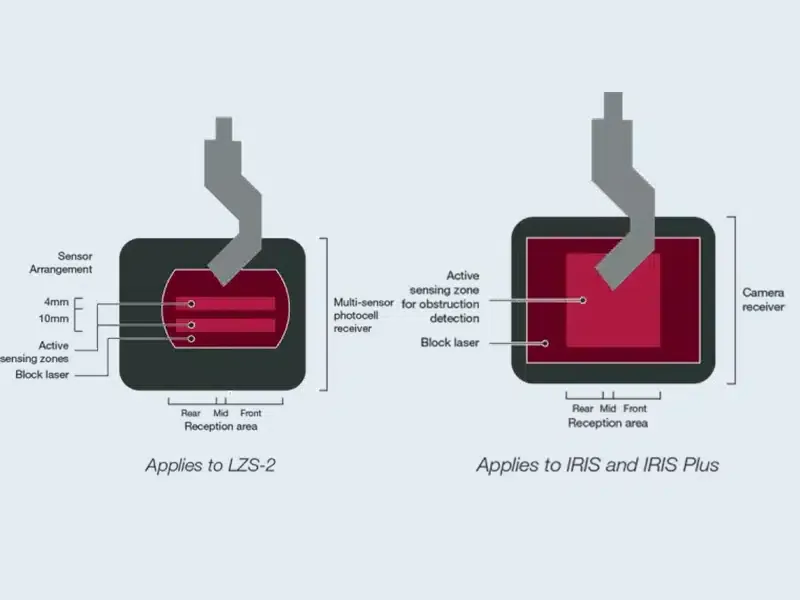

| Receiver type | Multi-sensor photocell | Multi-sensor photocell | Camera | Camera with integrated Intel? image processor | Camera with integrated high-speed Intel? image processor |

| Maximum recommended optical range | 8 metres | 8 metres | 15 metres | 8 metres | 4.5 metres |

| Minimum object detection resolution | 4mm | 4mm | 9mm | 2mm | 2mm |

| Connector type | M12 8 pin | M12 8 pin | M12 12 pin | M12 12 pin | M12 12 pin |

| Tool compatibility | V tools and non-standard tools | V tools and non-standard tools | V tools and non-standard tools | V tools and non-standard tools | V tools and non-standard tools |

| Integrated status LEDs | • | • | • | • | • |

| Special Functions | – | – | – | • | • |

| Automatic tool alignment | – | – | • | – | – |

| Automatic alignment confirmation | – | – | – | • | • |

| Special tools mode | – | – | – | • | • |

| Soft stop mode | – | – | – | • | • |

| Fast flattening mode | – | – | – | • | • |

| Automatic Cycle Start (ACS) | – | – | – | • | • |

| Bend Speed Management (BSM) | – | – | – | • | • |

| Adaptive Environment Sensing (AES) | |||||

| Technology | |||||

| RapidBend | – | – | – | • | • |

| RapidBend Ultimate | – | – | – | • | • |

| BendShield | – | – | – | • | • |

| BendVision | – | – | – | • | • |

| Performance / Minimum speed change point | |||||

| Flat sheet bending | 8mm | 4mm | 3mm / 10mm | 0mm | 0mm |

| Box bending | 8mm | 4mm | 3mm / 10mm | 0mm | 0mm |

| PCSS-A Series Compatibility | |||||

| PCSS-A0 / PCSS-A0 Plus | • | • | – | – | – |

| PCSS-A1 / PCSS-A2 | • | • | • | • | • |

| PCSS-A Tandem Adaptor | – | – | ? | – | – |

| Mounting Bracket Compatibility | |||||

| Economy Brackets | • | • | – | – | – |

| Standard Brackets | • | • | • | • | • |

| SmartLink Brackets | – | – | – | • | • |

| IRIS | IRIS PLUS | |

| Optical protection functions | • | • |

| Optical imaging functions | • | • |

| Maximum recommended optical range | 8 metres | 4.5 metres |

| Optical sensor | ||

| Camera | Digital Image Sensor | Digital Image Sensor |

| Frame rate / frequency | 17ms / 59Hz | Selectable 5ms / 200Hz or 10ms / 100Hz |

| Data resolution (sensor) | – | 0.01 degrees |

| Measurement technology | ||

| Type | Integrated | Integrated high-speed Intel? image processor |

| Intel? image processor | ||

| Memory depth | – | Records up to 10 seconds (2000 images) of bend data per cycle |

| Measurement accuracy | – | Up to +/- 0.25 degrees |

| Measurement rate synchronised with frame rate | – | Selectable 5ms / 200Hz or 10ms / 100Hz |

| Imaging technology | ||

| Bend Speed Management | • | • |

| BendVision | – | • |

| ECONOMY | STANDARD | SMARTLINK | |

| Specifications | |||

| Vertical bracket length | 700mm | 520mm / 700mm / 1000mm | 700mm |

| Vertical adjustment range | 488mm | 350mm / 530mm / 830mm | 500mm |

| Horizontal adjustment range | 40mm | 40mm | 40mm |

| Maximum recommended machine length | 4 metres | 15 metres | 6 metres |

| Main Features | |||

| Precision linear bearings and rails | – | • | • |

| Free sliding operation | – | • | • |

| Automatic motorised drive system | – | – | • |

| Maximum speed of the motorised drive system | NA | NA | 20mm/s |

| Adjustable locking handle | • | • | NA |

| Tool change lock | – | Manual | Automatic |

| Optics Compatibility | |||

| LZS-1 | • | • | – |

| LZS-2 | • | • | – |

| LZS-XL | – | • | – |

| IRIS / IRIS Plus | – | • | • |