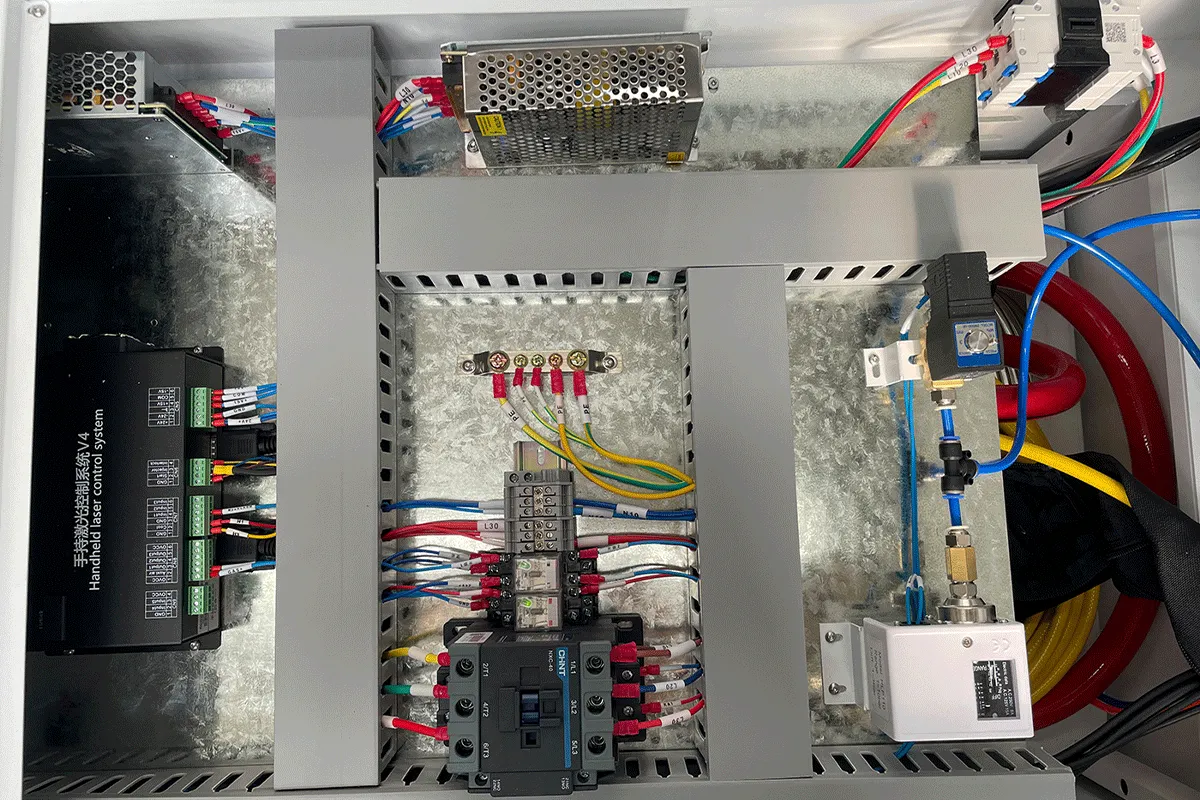

The machine is equipped with over-temperature alarms, flow protection, and water level protection devices to prevent hazards and ensure reliable operation. Comprehensive safety features prevent overheating and flow problems, thereby improving durability and operational efficiency.

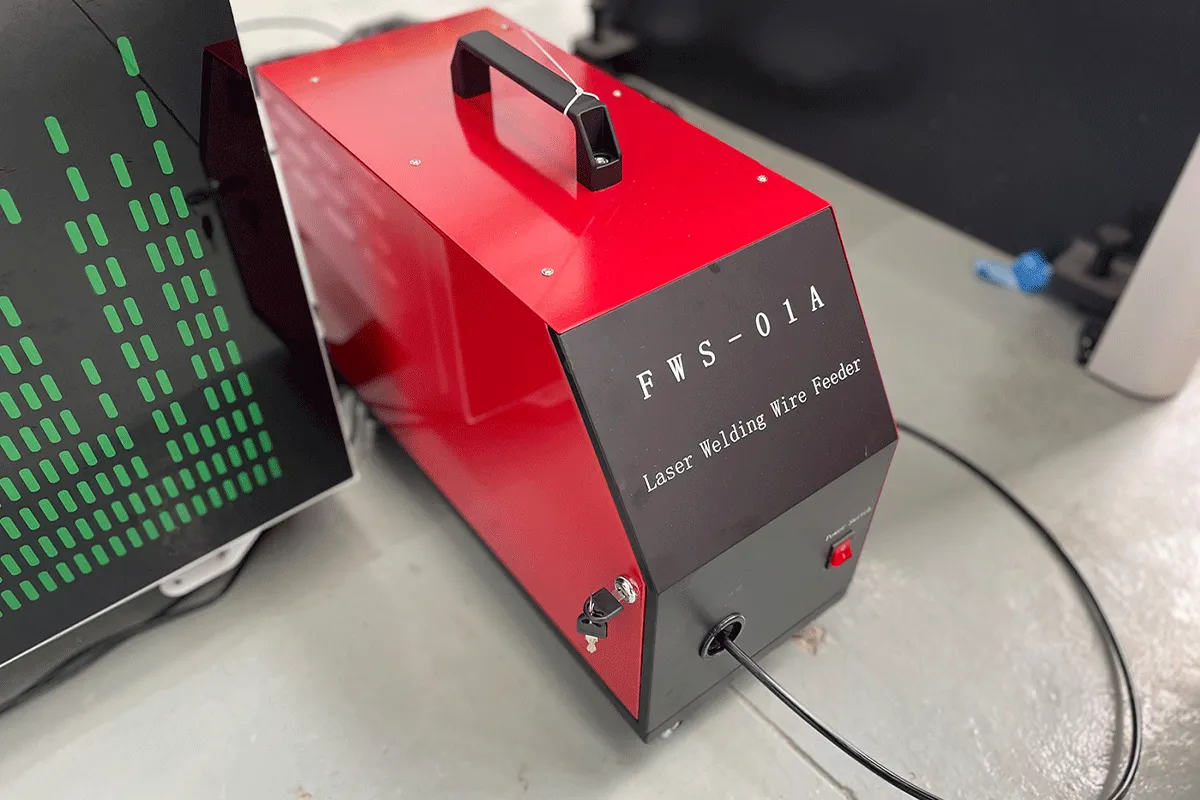

This fiber laser welding machine adopts a new generation of non-contact welding technology, which can operate without applying any pressure. Its working principle is to irradiate the material surface with a high-energy-density laser beam. Through the interaction between the laser and the material, the material melts internally, and then cools and crystallizes to form a high-strength, high-precision weld. This advanced welding method ensures minimal heat input and efficiently produces clean, high-quality welds. It is suitable for welding, cutting, cleaning, and rust removal of metals such as carbon steel, stainless steel, and aluminum alloys.