Tandem Press Brake Features

High Equipment Utilization: When processing extra-long workpieces, the machine can operate in tandem press brake mode. However, factory orders don't always consist of extra-long parts. When you only need one machine to operate, the two machines can work completely independently, which greatly improves equipment utilization.

One-Pass Forming for Extra-Long Workpieces: 8m, 10m or even longer workpieces (light poles, guardrail panels, container/trailer side panels, bridge formwork, etc.) can be completed in one pass, avoiding angle errors caused by secondary positioning.

Lower Total Cost: Compared to "giant" single machines of 8000mm/1000T or above: lower transportation and foundation costs, universal spare parts, and split maintenance downtime risks.

Easier Transportation/Installation: Standard models are easy to containerize and enter factories, especially factories with low ceiling heights.More friendly requirements for foundation load-bearing and hoisting

Tandem Press Brake Component

Sheet Follower: Smart sheet-follower technology keeps the workpiece perfectly supported throughout bending.Enables one-person handling of long sheets, improves angle consistency, and reduces scratches and ergonomic risk.

Sheet Feeding System: The integrated automatic feeding system greatly boosts productivity. It automatically positions, aligns, and feeds material, reducing manual intervention and improving process continuity. This is especially effective on large workpieces, significantly shortening cycle time.

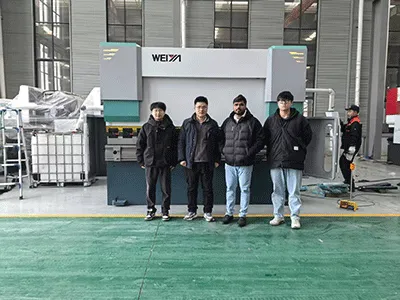

Flexible CNC Control Options for Every User: Our tandem CNC press brake offers multiple CNC control options to fit different needs and budgets. From basic 2D programming to advanced 3D simulation and online/offline programming, every operator can choose an interface that suits them. Intuitive touchscreens and guided programming make complex tandem operations straightforward.

Laser Angle Correction: Equipped with advanced laser angle measurement and real-time correction to ensure every bend meets the target angle. The system automatically detects material springback and adjusts bending parameters on the fly, achieving precise results without trial bends. This is especially important when switching materials or thicknesses, greatly reducing scrap and labor hours.