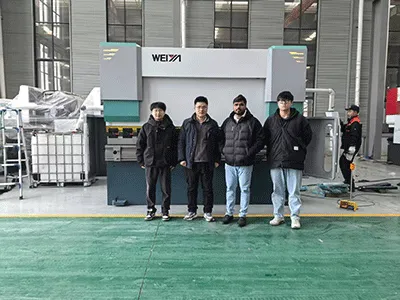

Elite CNC Press Brake 4-6 Axis Features

Advanced CNC Control System: Elite CNC control system such as DA66S, CT15 PS, ESA 650, both support 2D graphic function, can control up to 6 axis

High Precision & Performance Upgrade: With Z1 and Z2 axes and a more advanced main servo motor, the Elite series outperforms the smart series in terms of precision and is ideal for high-frequency, high-accuracy bending tasks.

Ideal for Versatile Industrial Applications: Suitable for medium-thickness sheet metal processing, control cabinets, automation shell equipment manufacturing, and other medium- to high-complexity bending tasks.

Excellent Cost-Performance Balance: It strikes the perfect balance between performance and affordability, making it ideal for growing businesses or production line upgrades.

Scalable & Future-Ready Design: Thanks to its modular design, the Elite press brake can be easily upgraded with IoT modules, real-time bending angle sensors, and other smart factory components.

Elite CNC Press Brake 4-6 Axis Component

DA66S System: Use friendly system specific suitable for new coming user or without experience operator. This system accept 2D program and 3D graphic, automatic bending sequence, and import the workpiece drawing directly into the system, no-pain for long time study let you start your business quickly.

6+1 Axis: 6 axis mean Y1,Y2,X,R,Z1,Z2, Z1,Z2 is the stop finger horizontal movement left and right, it could help to position the different width of bending plate. In conjunction with the CNC system, the Z1 and Z2 axes can automatically adjust the finger position, thereby reducing manual operation and improving production efficiency, especially in batch production.

Laser Safety Equipment: Risk always exists during machine operation. A serious accident can ruin a person's life, and the company will also be liable for heavy compensation. In comparison, investing in a laser equipment with a high level of safety protection is a very worthwhile investment.

Main Servo Motor: A servo motor will save 30% to 50% of electric power per year compared to a normal motor. A machine typically lasts at least 5 years, and its initial investment is only about 2,000 USD more than a normal motor.