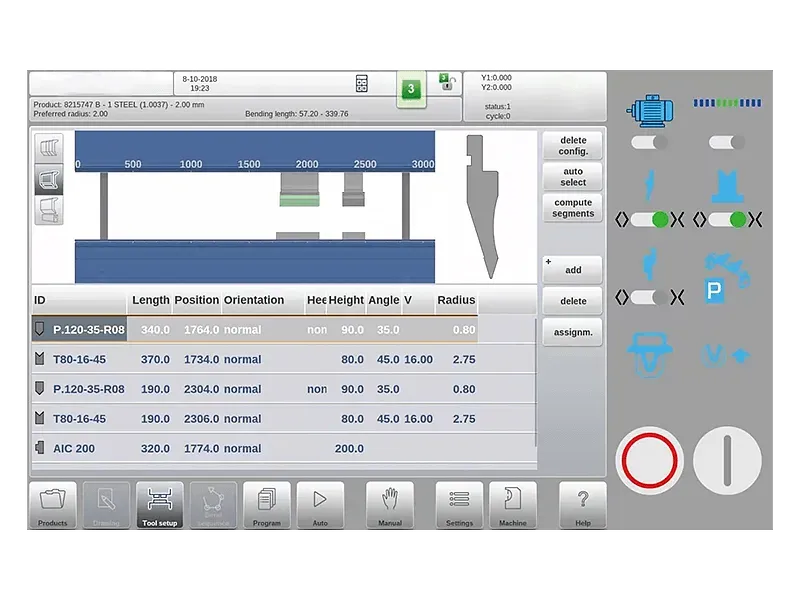

Smart Factory Tools for Industry 4.0 Access

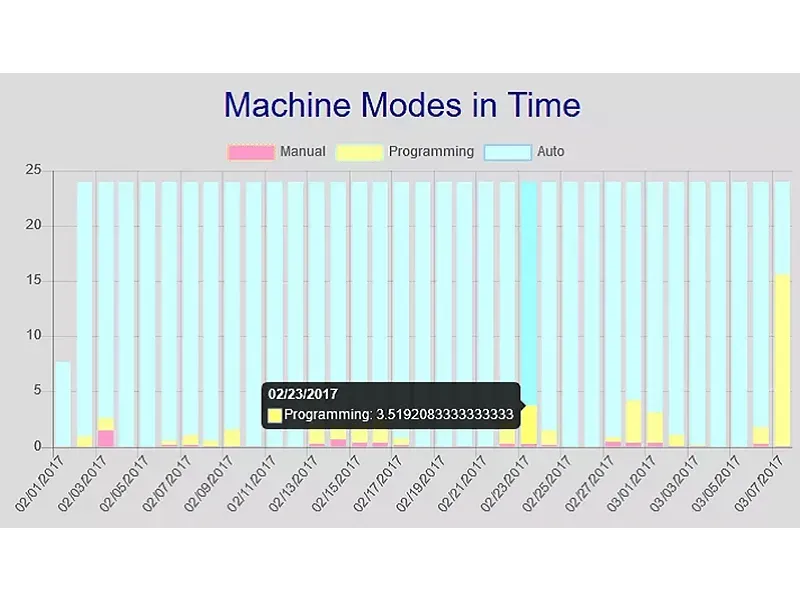

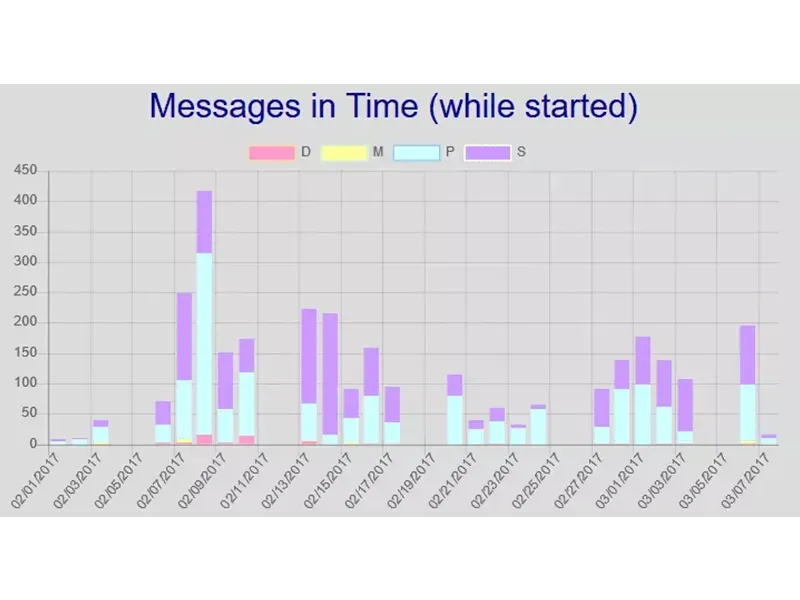

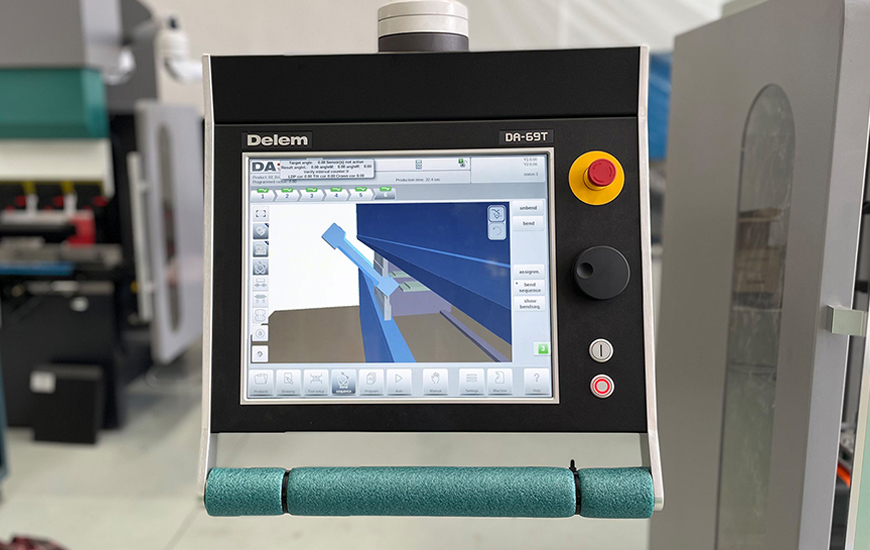

Advanced CNC and ad-hoc tools like "Smart Factory" enable companies to enter Industry 4.0—revolutionizing operations by unlocking cross-company data sharing: bending programs, sensors, and production stats.